The Billion-Dollar California Almond Industry’s Blossoming Future

Hint: This Future Involves the Auto Industry

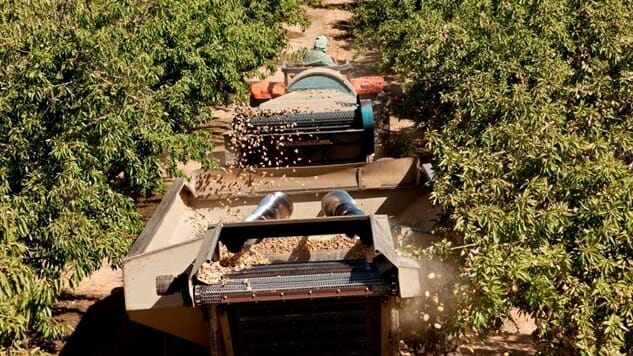

Photo by California Almonds

Almonds are the ultimate snack. Nutritious and satisfying, there’s a reason why these beloved nuts are pricey. According to the California Department of Food and Agriculture, California’s almond crops were valued at $5.33 billion in 2015. The year after that, the United States Department of Agriculture gave its approval for the Almond Board of California to raise its handler assessments from three cents to four cents per pound over the next three years in order to facilitate the goal of producing 2.6 billion pounds of nuts by 2020. With that in mind, the board hopes to increase global demand before this anticipated 25 percent increase in production.

Almond trees produce not only the actual almond kernels we consume, but also the hulls and shells which encase the nut as it develops. In addition, the tree itself is a source of essential woody biomass. These parts of the almond are known as coproducts. This year on Jan. 6, 2017, the ABC announced that it is actively seeking ways to better use these almond coproducts, in order to, “focus research investment on new uses which address manufacturing needs across several industries, among them food, automotive, pharmaceutical and plastics.” Given that California alone produces 80 percent of the world’s almonds and 100 percent of the U.S. commercial supply, the fact that the ABC is revamping its efforts to make the entire almond crop as profitable as possible could mean millions more in revenue for the already flourishing industry.

The California almond community has been diligent when maximizing the usages of almond coproducts. That said—due to market changes, fluctuations in the supply of livestock feed and bedding coproducts, as well as the demand of the dairy industry along with the advent of solar energy and wind mills, all result in a decline of cogeneration facilities (use of a heat engine or power station to generate electricity and useful heat at the same time), and it’s becoming increasingly tougher to recycle wood waste. The board estimates that for the 2015/2016 crop year, “over 1.5 million metric tons of hulls and over 0.5 million metric tons of shells were produced, with a growing proportion needing new outlets, preferably for higher value-added uses.” As a result, this organization is stepping in to help solve this issue. The goal? Zero-waste almond crops.

While this newly engaged strategic task force is giving the industry the opportunity to explore new and different ways to utilize coproducts, research and development is often uncertain and doesn’t follow a consistent trajectory. “Farms are becoming more like factories: tightly controlled operations for turning out reliable products, immune as far as possible from the vagaries of nature.” According to the Economist’s Technology Quarterly: The Future of Agriculture. “In the short run, these improvements will boost farmers’ profits, by cutting costs and increasing yields, and should also benefit consumers (meaning everyone who eats food) in the form of lower prices.” However, there are always the issues of cost efficiency, legality, scale, competition, and feasibility to take in to account.