Seems like everyone wants to be a brewer nowadays. When the line at the hyper-local taproom is out the door, it’s easy to forget how different the scale of operations can be between a booming microbrewery and a nationally distributed brand.

Each brewer’s journey is different, from the home brewer turned head brewer/owner to those climbing up the ranks from the cellar to the kettle, but the fact remains that the size of the company dictates the work experience. Matt Pollock is a brewer at New Belgium Brewing, the makers of Fat Tire amber ale, and the 4th largest craft brewery in the United States. He’s previously worked at much smaller operations: Rock Bottom Brewpub in Portland, Oregon and Indeed Brewing in Minneapolis, MN. Even though the fundamentals of brewing are the same, whether brewing at home or in a commercial brewery, as his jobs have changed, so has his brewing.

“The differences lie in the scale and nuance. At New Belgium, automation is important,” he says. “In one day of brewing at New Belgium, I probably produce as much wort as I did in one month at Indeed.”

After cutting his brewing teeth at Rock Bottom, Pollock moved to Indeed (about 15,000 barrels annually) and then to New Belgium in 2015 (roughly 1,000,000 barrels per year). At the young Indeed, Pollock’s processes were still being developed and perfected. “At first I performed mostly packaging and cellar work,” he says, but after a promotion to Lead Brewer, he took on supervising and training new employees and some recipe development. His time, he says, was split in many directions, shaping the company’s path. “As a growing start-up everyone had to be ready to chip in at any time, so knowing how to do every little task was key,” Pollock explains. “It’s a jack of all trades position, and with limited staff and resources, there was a lot of variety to the work.”

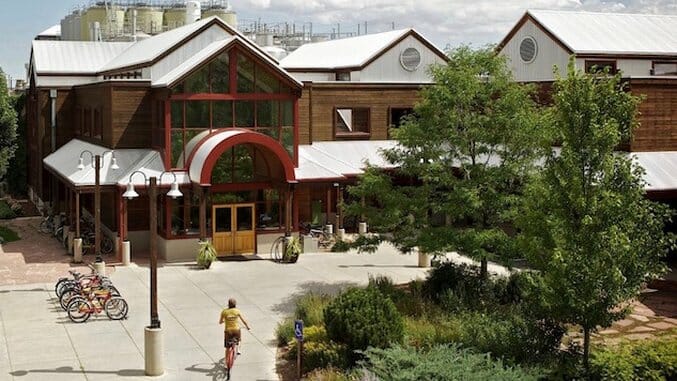

At New Belgium the work is task oriented, scheduled by shifts and highly specialized. He currently focuses on making wort in the brewhouse, while also helping with yeast operations. “I am assigned to those specific functions,” he explains. He’s one of 32 brewers on the staff, with five typically working a shift simultaneously—each assigned to a different part of operations. Indeed, he notes, employs six brewers total. Many start-ups have just one or two.

In Pollock’s experience, smaller breweries provide a greater range of daily work and a more direct impact on the company, but also longer hours and often less pay. It’s comparing a blank canvas to one that’s already been painted well, he says. At New Belgium, Pollock frequently working with some of brewing’s top talent, not just within the company but also with partner companies, suppliers, programmers, biologists… The work itself can feel further removed, he admits, but like any career, it comes down to company culture to truly define the experience.

“Brewers spend a lot of time together in close quarters under intense conditions,” Pollock says. “At New Belgium, we spend extra time during the hiring process determining the ‘cultural fit’ and I think that goes a long way.” At New Belgium, Pollock went through multiple interviews on brewing theory and problem solving, he remembers. One area that stood out, though, was after the final interview.

“Later that night we had some social time at a few local bars,” he says. “In hindsight [it] was probably to make sure I was a solid cultural fit with the rest of the team.” One can’t discuss brewing theory and technique without testing some product.