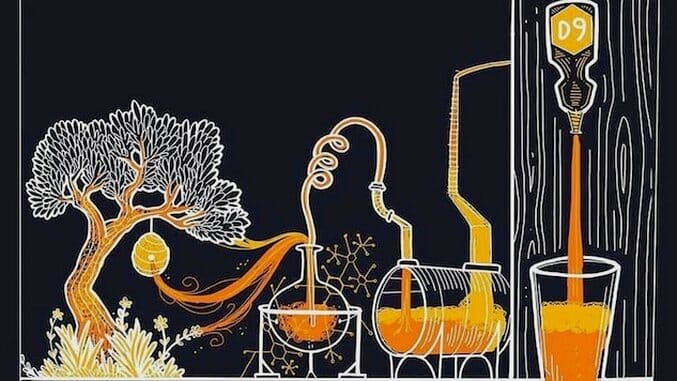

D9 Brewing is Sciencing the Sh!t Out of Beer

Artwork via D9 Brewery

As anyone who’s taken a tour of a brewery can testify, brewing beer is as much a science as it is an art. It requires an understanding of how all the ingredients chemically interact—steeping the grains to extract flavor, boiling out the sugar from the malted barley to make the wort, fermenting the beer and letting the yeast do its chemical magic. But D9 Brewing has taken that science aspect to the extreme.

“We create distinctive crafted ales by sciencing the shit out of them,” says Andrew Durstewitz, D9’s CEO.

The brewery certainly has the credentials back that up. It was founded by Durstewitz—who worked as an engineer for 15 years—along with another engineer and a doctor in late 2014. Today, the brewery is housed in a 12,000-square-foot production brewery in the Lake Norman town of Cornelius, North Carolina. Their mantra: invest in the scientific exploration of the natural world to produce the highest-quality, firmly original ales.

This vision came into fruition in 2017 when they launched their Taming Wild Beasts program. The goal, Dustweitz explains, is to develop new beers through the capture, purification, and cultivation of wild microflora. These precise scientific efforts resulted in capturing three key ingredients, each one purified and cultivated in their North Carolina lab from fruits and flowers culled from two continents: Felix, a brett wild yeast harvested from a Scottish flower; the Waterloom saccharomyces bacteria taken from the scuppernong grapes of North Carolina; and Lucian, a lacto strain harvested from the Calluna vulgaris flower. Unlike standard brewing processes, which typically adds ingredients either at the start or the end of the fermentation process, D9 adds their microflora at different stages in the fermentation process to deliver the flavor profiles they desire.

And their embrace of science doesn’t end there. After aging their wild beers in oak, they use a centrifuge that spins at nearly 8,100 revolutions per minute to clarify the brew, rather than the standard process of filtration. And then they assure that every drop of beer has the most minimal contact with the open air, lest it impact the beer integrity; they test to ensure that the dissolved oxygen in the beer stays below 16 parts per billion during the packaging phase.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-