From the Source: Cuban Cigars

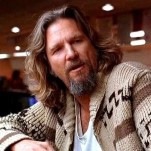

Photo: Flickr/Alex BrownAccording to legend, President Kennedy was partial to the H. Upmann brand of petit corona cigars. He enjoyed them so much he made a point to buy as many as possible up before it was too late. Sending his press secretary, JFK bought all of his favorite smokes within the Washington, D.C. area on February 6, 1962—the night before enacting the Cuba trade embargo. In the end, Kennedy collected around 1,200 cigars before signing the law into place on February 7.

While restored diplomatic ties between the U.S. and Cuba have brought a wave of travel interest to the destination known for producing world class cigars, don’t get too excited. The trade embargo is technically still in place.

However, the inability to stock up on stogies is the perfect excuse to plan a trip. If you are ready to pack your bags, you are in good company. Below is brief history and tutorial about cigar making and the best locations to enjoy the process when you arrive 90 miles south of Florida.

1. A Cure for What Ails You

The process of curing tobacco leaves after harvest usually takes around one or two months. In an effort to keep larger leaves from rotting, a combination of heat and shade reduces water and sugar content within the plant.

2. Smoke ‘em If You Got ‘em

Photo: Flickr/Thomas Münter

The second step is carefully fermenting—without disintegrating—the tobacco. Slowly drying the leaves determines the flavor and aromatic qualities of the cigar. Determined by color and appearance, the product is sorted to be used as filler or wrapper. Typically, the darker the tobacco, the more flavorful the smoke.

3. No Leaf Unturned

Tobacco leaves are baled to dry, inspected, and lastly un-baled to check appearance for categorization or to be cycled through again. Once the manufacturer’s expectations are met, the leaves are stripped from the stalk.

4. Wrap It Up

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-