Nisolo Shoes

Car batteries. Coffins. Shoes.

These three products are items where quality should not be ignored. Lead acid car batteries are vital in the cranking and performance of your vehicle; a good coffin with an even better seal keeps the buggies off of you after you croak, and most importantly, you are on your feet every day. Your feet deserve something nice.

That is where Nisolo shoes come into the picture. Nisolo makes high-quality, handcrafted leather shoes and accessories in Peru. These Peruvian shoemakers have grown up in the local shoe industry for generations and are the epitome of few artists left around the world who view a handmade leather shoe for what it is—a work of art.

Nisolo is a socially conscious brand dedicated to offering a unique product that fuses quality and fashion with a vision to spur sustainable development throughout impoverished regions of the world. A Nisolo purchase is a direct investment in the future of the impoverished artisan who crafted it. Supporting Nisolo allows the consumer to directly impact one of the most powerful forms of poverty alleviation: job creation. The team at Nisolo follows the general mantra that wearing Nisolo means wearing change.

And Nisolo’s shoe designs happen to look damn smooth, too.

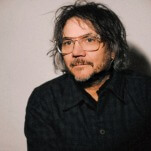

We had the opportunity to sit with Nisolo founder and CEO Patrick Woodyard to ask him some direct questions about the economic impact, style and history of Nisolo.

Paste: How and why did Nisolo start? Who are the founders?

Woodyard: Well, I am the CEO. I work with Zoe Cleary and Nick Meyer who make up the executive team. More importantly, we have a team of 30 shoemakers in Peru, including three Peruvian managers. I spent a few years working in developing countries before Nisolo got started. My passion and experience working with sustainable poverty alleviation programs eventually led me to a year in Peru, where I worked with a micro-finance organization striving to lift impoverished women and their families out of poverty by creating and maintaining sustainable micro-businesses. This experience eventually led to the creation of Nisolo. One of the husbands of one of our clients, Willan, was a shoemaker, and he introduced me to a massive community of shoemakers in Trujillo, Peru. Upon seeing their remarkable talent yet lack of access and inability to provide for their families, I was led to start Nisolo as a means of providing the “access” they lacked to grow their businesses.

Paste: How long has Nisolo been in operation?

Woodyard: The idea for Nisolo was born in November of 2010, and our team did not begin working full-time on the venture until July of 2011. We were able to fully launch our product line in October of 2011.

Paste: What makes a Nisolo shoe better than a shoe made from other countries? Essentially, why Peru?

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-