Bardstown Bourbon Co. and WV Great Barrel Company Explore the Evolution of the American Whiskey Barrel

Photos via WV Great Barrel Co., Bardstown Bourbon Co., Jim Vorel

One of the most central, inherently important questions that any whiskey industry company must answer before launching is the following: What is this company’s relationship with tradition?

That is not a query you might see whiskey geeks mulling over particularly often, but it’s an absolutely essential facet of a new distillery deciding exactly what it intends to be. How important is the history of whiskey production? How inviolable are the methods by which whiskey has been produced over the last few centuries? Beyond the rigid federal definitions for a term such as “bourbon,” how much value do they place into techniques, aesthetics and ideals established far in the past, and how hesitant are they to flip the script if the data suggests there may be a theoretically better way? The answer to these questions will have vast ripple effects in determining what techniques and philosophy a new distillery will choose to employ. And for a cooperage, where the barrels used by the industry are built from the ground up? Those questions are even more important.

The people behind West Virginia Great Barrel Company asked themselves all of those questions, and what they settled on was that although tradition may inspire the cooper’s art, it can’t dictate how they assemble a barrel. Instead, this is a young company driven by achieving the best possible result by any means necessary, even when it runs counter to what may have long been considered “conventional wisdom.” And what better partner to find at the intersection of how barrels and whiskey interact than Bardstown Bourbon Co.? Driven by blending and experimentation, Kentucky’s BBC has rapidly come of age since debuting as an esoteric young face of the bourbon scene back in 2014. Together, these two companies have come together to advance the state of the American whiskey barrel, an endeavor that could have profound ripple effects through the whiskey industry and far beyond.

Rethinking the Whiskey Barrel

The standard American white oak whiskey barrel used for the maturation of the vast majority of bourbon or rye is something of a beloved antique—the process for making a barrel was established nearly two centuries ago, and in many places it’s barely changed at all. Skilled coopers are absolutely essential to this process, because many barrels are made with a large degree of manual involvement—literal men with hammers, aligning staves and placing hoops. It’s a highly specialized field, but one where change arrives only slowly, if at all. Some whiskey industry observers would romanticize this aspect of cooperages, as living time capsules where barrels are made in a manner one can realistically describe as “artisanal.” WV Great Barrel Company, on the other hand, looks at those processes and discards the sentimentality, preferring to tinker in any process they believe will yield a superior barrel. Which is to say, a barrel that better holds new-make whiskey without leaking, and imparts better flavor (subjectively, of course) to that whiskey. In doing so, they refer to themselves as “the world’s most advanced whiskey barrel cooperage.”

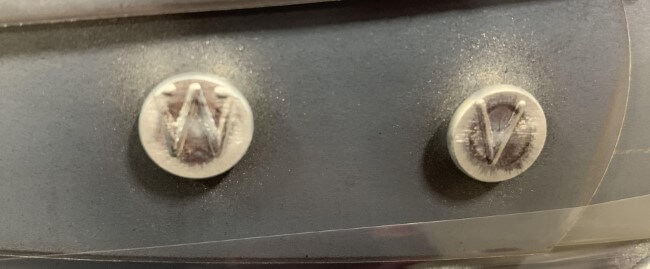

Easiest way to spot a barrel from WV Great Barrel Company? The custom rivets.

Easiest way to spot a barrel from WV Great Barrel Company? The custom rivets.

As stated previously, some of these processes run counter to what is widely considered traditional or common knowledge. For instance, many cooperages place a high value on the air drying of staves for whiskey barrels, commonly referred to in the industry as “seasoning.” This process helps to break down wood tannin over longer periods, resulting in a whiskey that takes on less undesirable tannic dryness after a relatively short time in the barrel. Many cooperages will season their staves for six months or more, and you won’t have to look far in order to find distilleries boasting of aging their whiskey in barrels made from oak that was seasoned for a year or beyond. WV Great Barrel Co., on the other hand, seasons most of its barrels for only three months, not because they welcome more tannin in their product, but because they believe in breaking down that tannin with a different process.

That process is toasting, a dimension of the whiskey barrel industry that has steadily come into vogue over the last half decade. Surely, you’ve seen the various “toasted barrel” releases sitting on shelves, although merely seeing the word “toasted” on a label ultimately tells one very little. As for what toasting is, it’s pretty much exactly what it sounds like: Exposing a barrel to a mild heat that does not char it, but instead dries it through more gentle transfer of energy, caramelizing wood sugars and breaking down tannin in the process. A toasted barrel can then be used as a finishing barrel for whiskey, or it can be newly charred after toasting, which does not destroy the toasted layer as one might expect. Rather, the main function of toasting is to drive the so-called “red layer” of the barrel further into the wood, as this area contains most of the chemical compounds that give American whiskey its signature flavors as it interacts with the wood—caramel, vanilla, spice, etc. The charred layer, on the other hand, primarily functions as a charcoal filtration system, rather than a flavor delivery vehicle.

WV Great Barrel Co. doesn’t place much emphasis on the air drying, because they’re extremely focused on reinventing the process of toasting, which they believe brings the same changes to a newly constructed barrel, albeit much more efficiently. Nor do they see toasting as an artisanal process, romanticizing the use of open flame—rather, they want to rigorously control the exact level of toast as closely and consistently as possible. To this end, they’ve pioneered the use of infrared technology for all of their toasting, with no involvement of fire at all. Over the course of 16 minutes, exposed to infrared radiation, a WV Great Barrel Co. worker can deliver any number of custom toast profiles, with a degree of consistency that the company claims is not achievable using the more traditional method. They then apply the same scientific rigor to their barrel chars as well, utilizing precise temperature measurement and control for consistency, rather than the intuition of some grizzled master cooper.

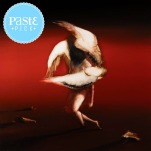

Flavors the company hopes to impart with various toast levels.

Flavors the company hopes to impart with various toast levels.

This level of control over the entirety of their process makes WV Great Barrel Co. particularly suited for making extremely specific, proprietary barrels with custom toasts and chars (and even different types of oak) for a variety of small distillery clients. Some of those clients are truly exploring the vanguard of American whiskey aging, utilizing cutting edge techniques in the pursuit of the next big thing in the whiskey world—stuff we still won’t taste for a few years in many cases. Many are experimenting with barrels that combine such elements as a very light char, with a heavy toast, effectively choosing to drive flavor into the spirit with the depth of the toast, rather than a char. And because even a level 1 char still works just fine for filtration purposes, this kind of thinking is upending even the preconceptions of distillers and blenders in terms of what kinds of barrels they really want for their products. It’s ushering in a new era, with a much wider variety of choices available to people making American whiskey.

This year, WV Great Barrel Co. will produce somewhere in the neighborhood of 125,000 standard, 53 gallon barrels, but rapid expansion hopes to double and triple that number in the next few years, thanks in part to the company’s embrace of automation. You can expect to hear the name more and more often in the future, especially as collaborations like their one with Bardstown Bourbon Co. gain the attention of writers and drinkers.

Bardstown Bourbon Co., Cherry Oak and Rye Whiskey

A new collaboration brand from WV Great Barrel Co. and Bardstown Bourbon Co. illustrates exactly the kind of unique flavors that these custom barrels are capable of unlocking. This entry in the distillery’s Collaborative Series, released at the end of 2022, brings together sourced rye whiskey, Canadian corn whiskey, and a barrel unlike anything I’ve seen before.

These barrels, custom built for the collaboration, are composed of alternating staves of standard American white oak and cherry oak, with two different toast profiles. Thus, in the finished barrels, each stave alternates between lightly and medium toasted American oak and cherry wood. The alternating staves were chosen to impart a more gentle cherry oak profile, rather than constructing an entire barrel out of this wood. These specially constructed barrels were then used to finish (for 10 weeks) a blend assembled by the BBC team, consisting of 7-year-old rye whiskey from MGP, and 12-year-old Canadian corn whiskey.

The effect is pretty dramatic, especially to someone who has tasted more than his fair share of sourced MGP rye whiskey over the years, as the cherry barrel-finished rye displays an assertive and complex profile of fruit and baking spice. Confectionery notes of cherry tart and toasted oak are featured heavily on the nose, while the palate is rich and redolent in cinnamon, nutmeg and allspice, along with vivacious herbal notes from the MGP rye. It’s a warm, sweet dram laden in festive spice, feeling very much at home in the holiday season. It’s also a world apart from how this spirit likely tasted before entering the finishing barrel.

The people at Bardstown Bourbon Co. are certainly a fan of the profile. They liked it so much, in fact, that the inaugural rye whiskey release in their upcoming Origin Series —the debut of BBC’s own distillate, with no sourced whiskey—in early 2023 will also be finished in the same infrared toasted cherry wood barrels from WV Great Barrel Co. The Origin Series will also include two bourbons—a rye bourbon and a wheated mash bill—but by dedicating their first in-house rye to the cherry barrel process, the company has signaled how much they believe in WV Great Barrel Co.’s product, and the potential of this approach to transform the whiskey world.

Because there’s such a long lead-time on the development of new processes as applied to whiskey—because the spirit must age for years in various barrels, unless they’re finishing barrels—the full effects of something like WV Great Barrel Co.’s innovation with toasted barrels won’t be felt for some time. Personally, I find myself wondering how the slow accumulation of high-quality toasted barrels might some day affect the world beyond whiskey. After all, it stands to reason that if toasted barrels of this nature yield a different strain of bourbon or rye, they’ll also bring new flavors slowly but surely into all the industries that re-use those American whiskey barrels, such as aged rum, tequila and scotch whisky. Could it be that a decade from now, boutique rum and scotch brands will be purposefully seeking out specific types of re-used toasted barrels, like the ones out of WV Great Barrel Co., to use for their single barrel expressions? Perhaps this evolution of the American whiskey barrel will go on to be even more significant than anyone realizes.

Jim Vorel is a Paste staff writer and resident liquor geek. You can follow him on Twitter for more drink writing.